- to evaluate a Model Number not shown in the calculator. Frictional head loss and pressure drop calculations are done with the Excel formulas in the spreadsheet template using the Darcy Weisbach equation.

Shell Tube Heat Exchanger Video Webbusterz Engineering

Support SI Units and English US Units of measurement.

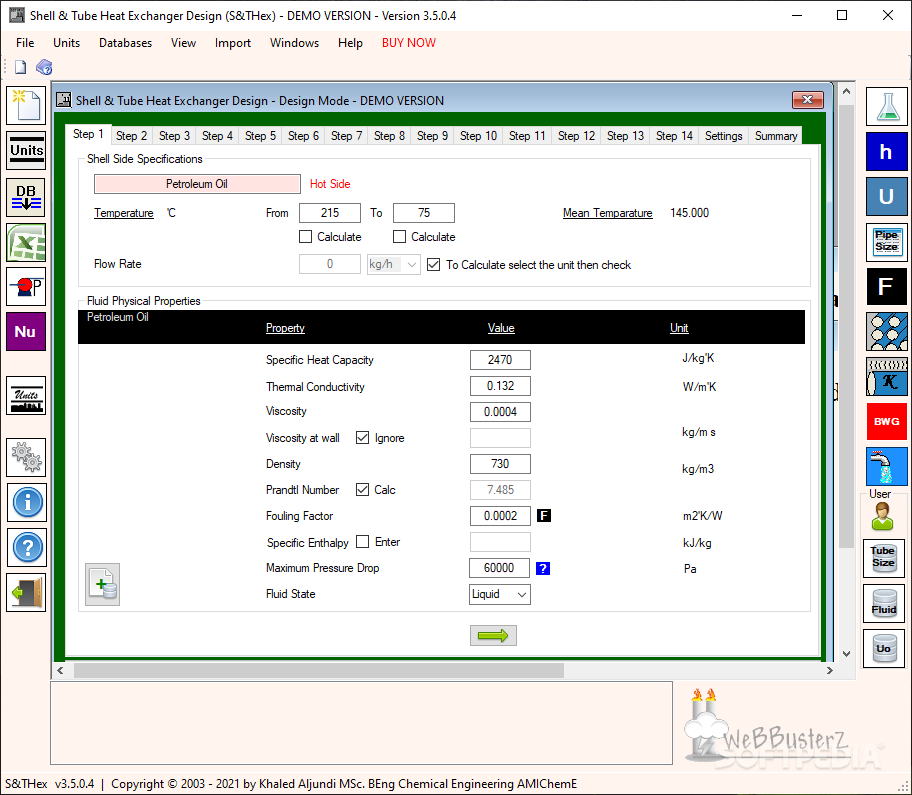

. The vendor receives the design develops drawings and builds the exchanger. Enter the fluid Flow Rate Temperature and Pressure at the heat exchanger. Shell and Tube Heat Exchanger Software Features STHex Step by step design and rating calculations.

Mechanical engineers do extensive work on exchanger design to fully specify the exchanger eg. 3000 INR 60 USD. Shell and Tube heat exchanger design Software Features.

Select a suitable type of shell and tube exchanger. Step by step design and rating calculations. SHELL TUBE HEAT EXCHANGER Equipment label Shells per unit Series Parallel Surface per unit Process service Plant section Equipment name Surface per shell.

Shell Tube type segment dominated the heat exchangers market in 2018 Shell tube is the most widely used types of heat exchangers that accounted for the significant share of the heat exchangers market in 2018. Design pressure at max temp Dynamic viscosity Film transfer coefficient Square Triangular 100 100 100 100 100 ft2 m2 ft2 100 ft2 m2 ft2 100 lbh kgh lbh 100 lbh kgh lbh. MS Excel features Programming of ST HE.

ACTUAL TUBESHELL TABLE LOOKUP TUBESHELL TABLE Shell ID 34 tubes 1 tubes 1 14 tubes 505 505 505 505 1900 800 400. This web application estimates LMTD Log Mean Temperature Difference Exchanger surface area number of tubes shell diameter and number of. - if you need a custom designed heat exchanger.

-1 input physical properties at bottom. Shell and tube heat exchanger design is an iterative process which goes through the following steps. I r research e s air mit.

Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being. This should be treated as a quick check for budgetary proposals only. Drawing for Horizontal Position.

By WeBBusterZ Engineering Software. Ustart 100000 Wm C Then the required transfer A Number of tubes required No. Units for double pipe and shell and tube heat exchanger design.

Heat Exchanger Design in Excel Spreadsheet. Save Load and. Properties of air and water useful for convection calculations.

Calculation of ST heat exchanger area sizing. Be careful to explicitly state who if anyone will provide thermal or hydraulic guarantee. HEAT EXCHANGER CALCULATIONS AND DESIGN WITH EXCEL JUNE 21ST 2018 -.

Contents Shell and Tube Heat Exchanger Applications Different Design Methods. This template calculates the size of an ST heat exchanger. For more information please visit the Products page.

This is a calculator for sizing a shell and tube heat exchanger with tubeside flow fixed. Select a Tube Side product fluid and Shell Side working fluid. Tube and fin material.

Up to 24 cash back Shell and Tube Heat Exchanger BEU Design Estimation Spreadsheet. Shell tube heat exchangers can manage fluids at high temperatures and pressures due to which they are preferred. 99087872 Above pressure drops tube and shell are within allowable limits.

Support SI Units and English US Units of measurement Units converter is also included. I am new to this website I wanted to share a few spreadsheets dont know whether this where I should share the file or not. Heat exchanger calculations and modeling to get the output.

Excel spreadsheet engineering workbook heat exchangers rule of thumb for engineers Description The principle objective of this workbook is to demonstrate the use of the Bell-Delaware method for rating shell-and-tube heat exchangers. For known shellside and tubeside dimensions heat. 9-11 HC Oil.

Design calculate core length from cooling load. Define process requirements for the new exchanger. Step by step design and rating calculations.

Shell and tube heat exchanger step by step calculations. The log mean temperature difference LMTD is also reported. The configuration gives a large surface area in a.

Unknown exit temperatures on both sides or Unknown two Temperatures one shell side and another tube sides. Tubes baffles shell size tie rods sealing strips skid bars etc. Use your local currency such as kg.

ASME SecVIII Div1 and TEMA. Duty Area Shell and Tube velocities Number of. Design A Shell Tube Heat Exchanger On Ms Excel - posted in Process Heat Transfer.

This Heat Exchanger Excel Workbook provides well organized technical data in form of spreadsheet calculations tables charts and diagrams indispensible for anyone involved in the. Choose a Model Number. With shellside and tubeside inletoutlet temperatures fixed the required shellside flow is calculated corresponding to given tubeside flow.

Actual heat exchanger design should be carried out in reputable software like HTRI or HTFS for actual procurement. Please note that the software can only do the basic chemical design rating calculations of shell and tube heat exchangers and some mechanical design calculations. Velocity 41714 531 4 134 000900 0001254 0139284 m.

Shell and Tube Heat Exchanger Most commonly used type heat transfer equipment in chemical and allied industries. Unknown Flow rate Unknown temperature on either shell or tube side can be calculated. Begin with the assumed overall heat transfer coefficient to this point.

Shortcut Heat Exchanger Sizing. Design Calculation of Parts. This is a simplified tube-shell heat exchanger design.

Rating and Design Modes. Up to 10 cash back Get access to valuable shell and tube heat exchanger design tables according to DIN 21184 - 21191 and TEMA std to properly design shell and tube heat exchangers. Selected Base Values from Fig.

Heat exchanger is adequately sized. To calculated U in Step 7. Of passes Tubes per pass Area of tubes per pass Volumetric flow Av.

Dimensional Sketch of Body Flange. Finned tube heat exchangers thumb rules process heat. Define design parameters such as - number of tube passes tube size shell ID etc.

Start configuring the exchanger. Calculate f psi Calculate sum of heat transfer resistances Fouling resistance Calculate U btuhr-sqft-degF Compare required U in Step 3. Excel spreadsheet templates can be downloaded in US.

The pressure drop calculated for shell and tube heat exchangers is that.

Rohger Service Technology Technology Room Divider Home Decor

How To Design A Tubular Heat Exchanger Hrs Heat Exchangers

Download Shell And Tube Heat Exchanger Design 3 5 0 6

Heat Exchangers Design And Calculation Excel Workbook Youtube

Download Shell And Tube Heat Exchanger Design 3 2 0

Download Shell And Tube Heat Exchanger Design 3 5 0 6

Centrifugal Pump Types Centrifugal Pump Pumps Piping And Instrumentation Diagram

0 comments

Post a Comment